How can companies determine the optimal level of (de)centralization for their supply chains?

March 05, 2018

A new publication from Horst Treiblmaier from the Department of International Management investigates different options companies have to make their supply chains more resilient. External forces can lead to disequilibrium states which are characterized by inefficient control structures and decision making processes. Frequently, such developments are triggered by changes in the external environment.

It is still an unresolved issue in academia as well as in the industry which level of centralization of organizational control structures is ideal to cope with such external changes. To tackle this problem, Treiblmaier compiled literature sources and compared various conflicting opinions on the subject. Not surprisingly, some authors favor a decentralized approach while others argue that the centralization of authority makes decision processes more efficient. However, he found that the best approach might be a differentiated view in which certain contingencies are taken into account.

A survey among 111 industry professionals revealed interesting insights on how companies structure their operations and deal with external disruptions. Exemplary measures include the selection of regional suppliers and customers, clearly defined responsibilities, delegation of decision making and shared research and development.

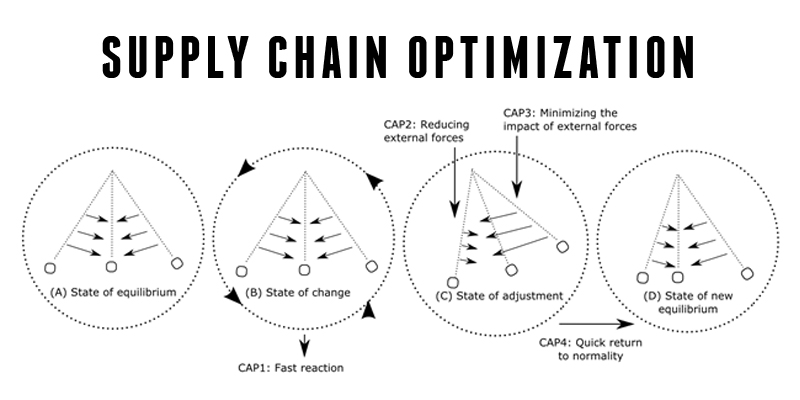

The results of the survey were condensed with a principal component analysis and finally led to four major capabilities which companies need to possess to be able to cope with fast changing environments: (1) fast reaction, (2) the reduction of external forces, (3) minimization of the impact of external forces, and (4) a quick return to normality. Of course, different capabilities are needed to excel in the respective categories, which are elaborated in more detail in the paper published in the International Journal of Logistics Management.